Sales office

104, S.V. Industrial Estate, Handewadi Road Hadapsar, Pune 411028, Maharashtra, India

Telephone : +91 9922009135

Email: sales-india@gearspect.com

104, S.V. Industrial Estate, Handewadi Road Hadapsar, Pune 411028, Maharashtra, India

Telephone : +91 9922009135

Email: sales-india@gearspect.com

Measuring instrument for complete testing of form geometric deviations of involute gearing, i.e. profile, lead, pitch and radial run-out, dia over ball, span, etc. Evaluation is realized according to DIN, AGMA, ISO and GOST standards with PC protocol print-out. The tester's accuracy is attested by statistics SW qs-stat 3.2 and VDI/VDE. Optional SW available for inspection of Hob after resharpening, PC based automatic measuring cycle.

Measuring instrument for complete testing of form geometric deviations of spur involute gearing, ie. Pitch, profile, helix angle, radial run out and check dimensions, up to dia.500mm.

Measuring instrument DO -3i PC for testing of geometric deviations in spur and helical gears i.e. Lead, Profile and pitch errors along with run out, base tangent length, dimension over ball etc.

Measuring instrument G-260

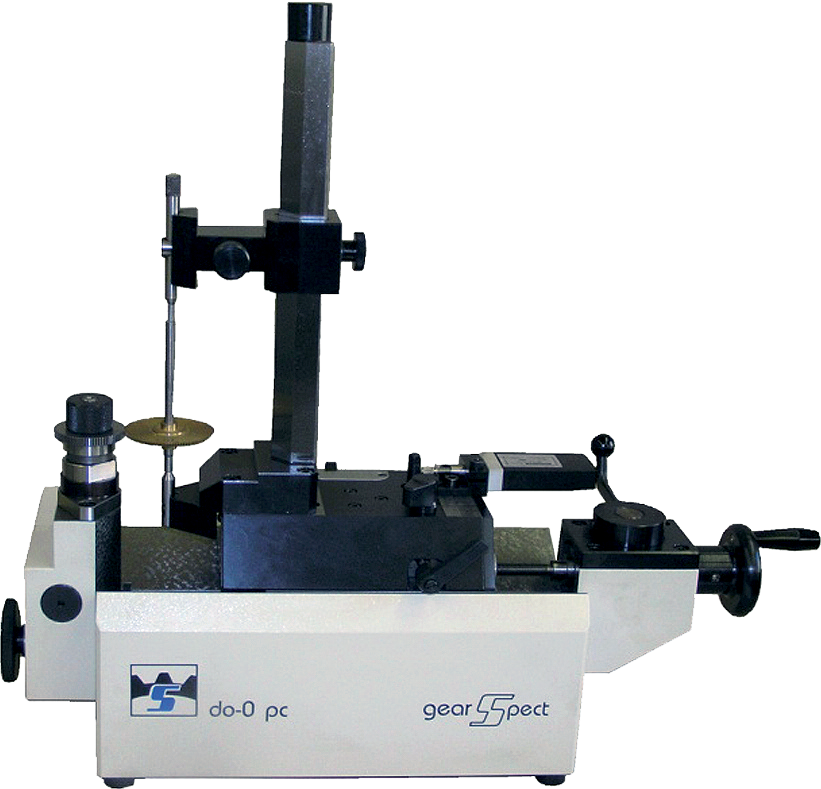

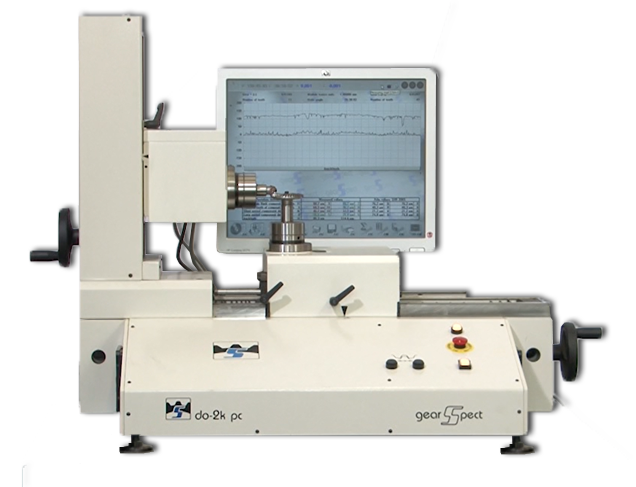

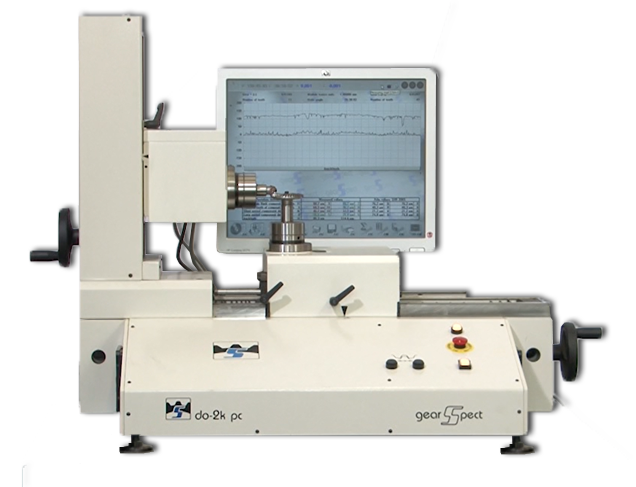

Test deviations of small diameters spur gears by double flank rolling method with master gear, scanning and evaluation by PC.

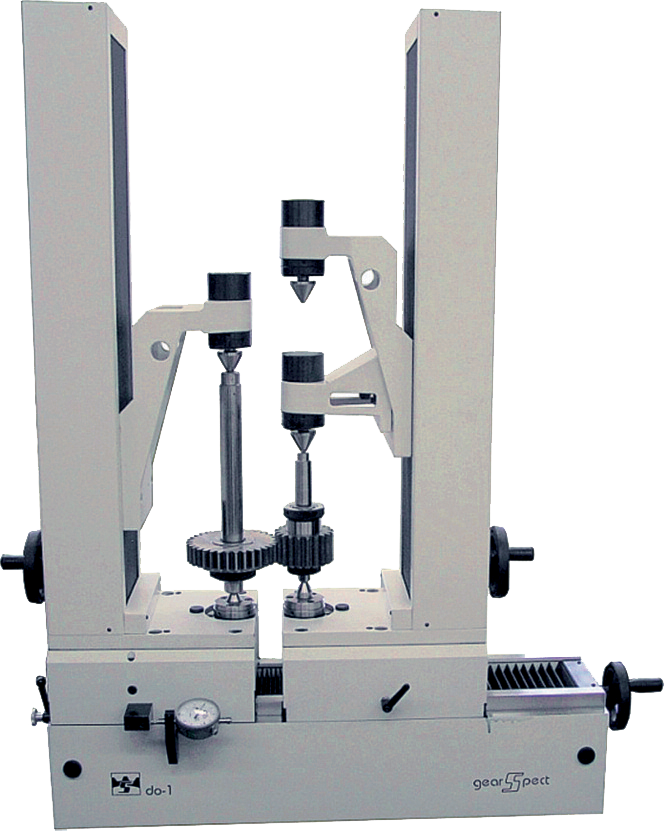

Test deviations of double flank and Mdk of shafts and spur gears. Scanning and evaluation by PC.

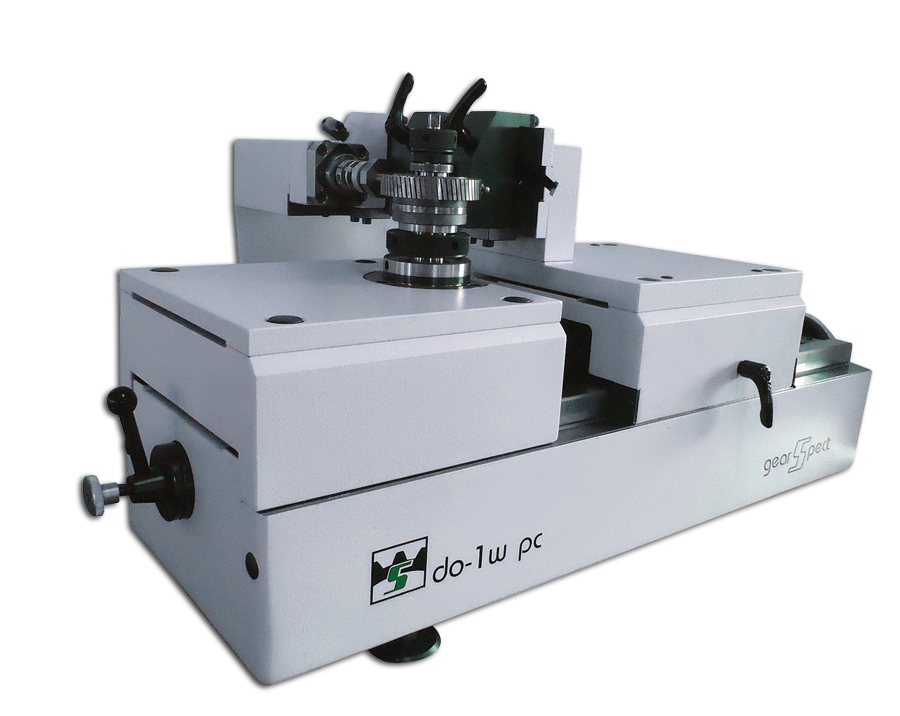

Computerised double flank evaluation of Spur/Helical gear with dual station facility to acctive highest productivity.

Test deviations of double flank and Mdk of internal gears.

.jpg)

Test deviations of worm gears by single flank rolling method, evaluation according to DIN and AGMA standards with output on PC.

Measuring instrument for testing worm gearing by single flank rolling method. Scanning and evaluation by PC.

Measuring instrument for testing of bevel gearing by single flank rolling method. Angle of crossed axes is 90°. Scanning and evaluation by PC.

Measuring instrument DO 2S PC for testing worm gearing by single flank rolling method. scanning and evaluation by PC.

Enables conventional double flank test of bevel gears. Reading and evaluation using dial gauges

Measuring instrument. Enables computeried double flank evaluation of worm. Minimum/Maximum axis distance 35-50mm

Measuring instrument DO 140 K PC for testing of bevel gearing by single flank method, Scanning and evaluation by PC.

Simple manual measuring instrument for testing of bevel gearing by double flank rolling method. Angle of crossed axes is 70°-120°. Scanning and evaluation by dial indicator.

Measuring instrument IMO 1000 K/W CNC for testing of big bevel and worm gearing by single flank rolling method. Scanning and evaluation by PC.

Measuring instrument for testing of big bevel gearing (and hypoid bevel gearing) by single flank rolling method. Scanning and evaluation by PC.

Measuring instrument for testing of big bevel gearing by single flank rolling method. Scanning and evaluation by PC.

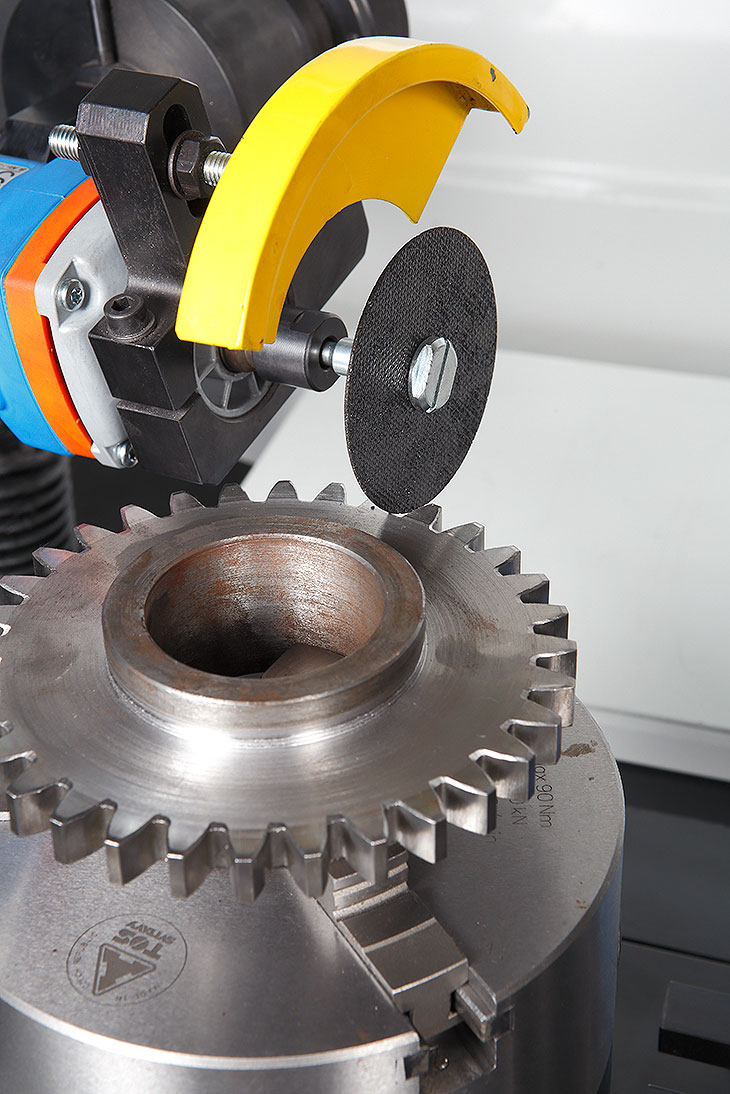

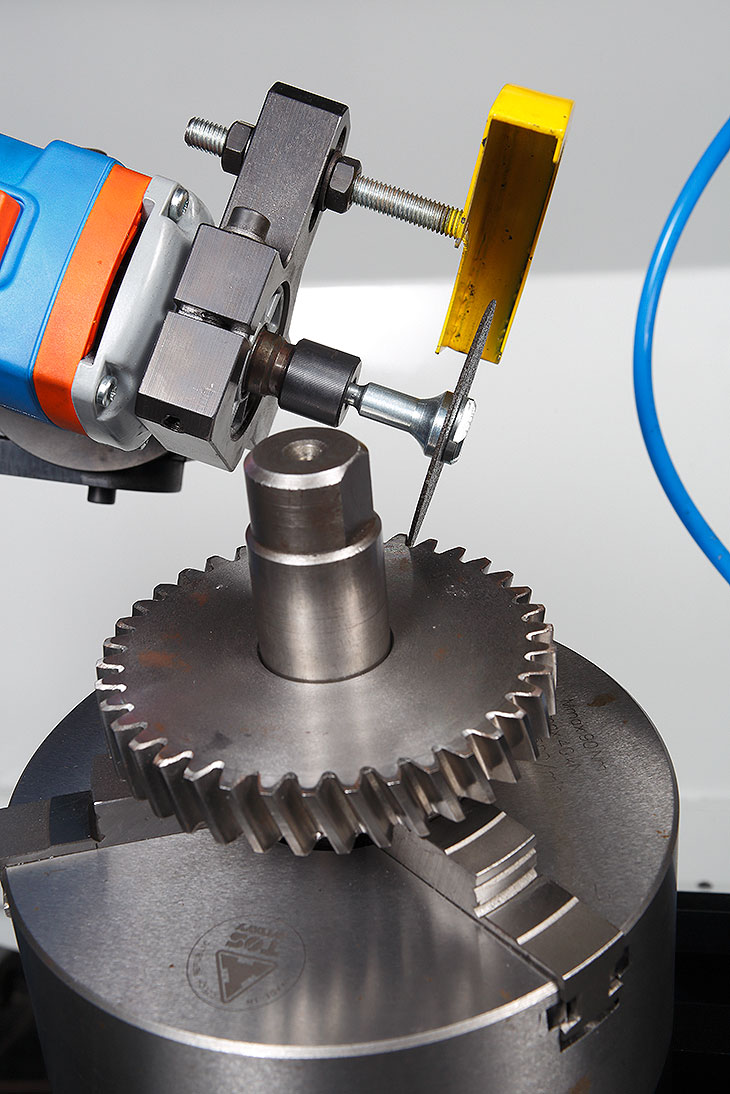

The machine serves for deburring of spur gears both external and internal also incl. chain wheels in single and mass production.